ClimeEvent & TempEvent

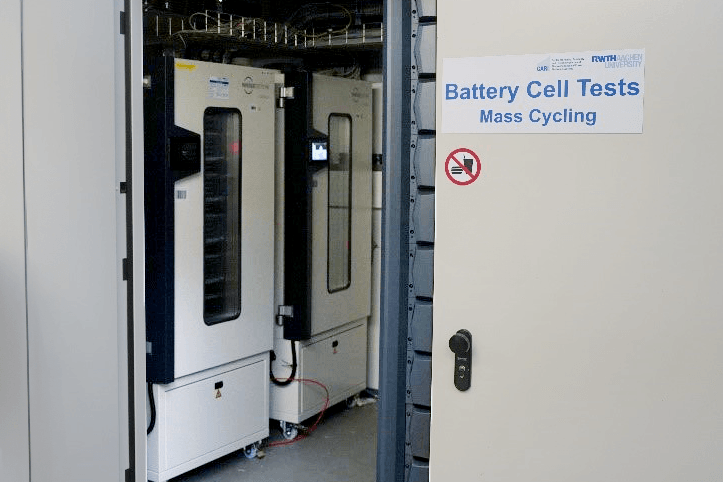

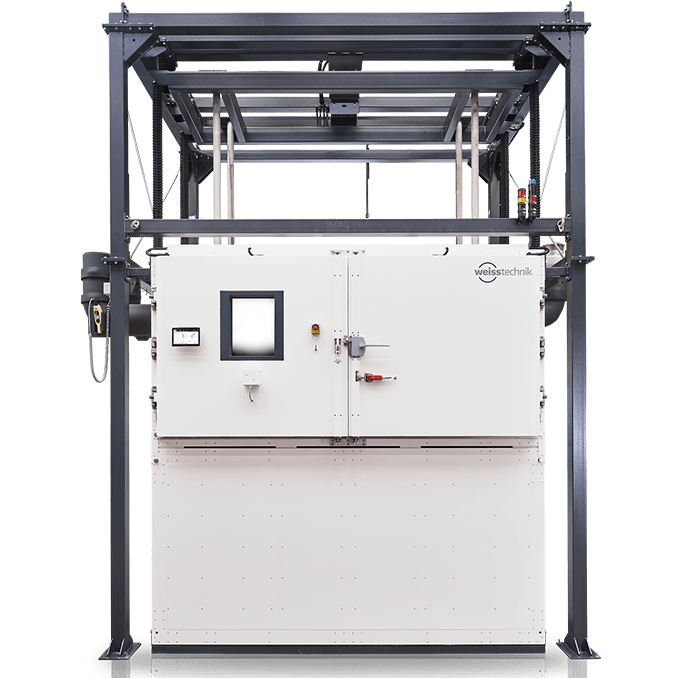

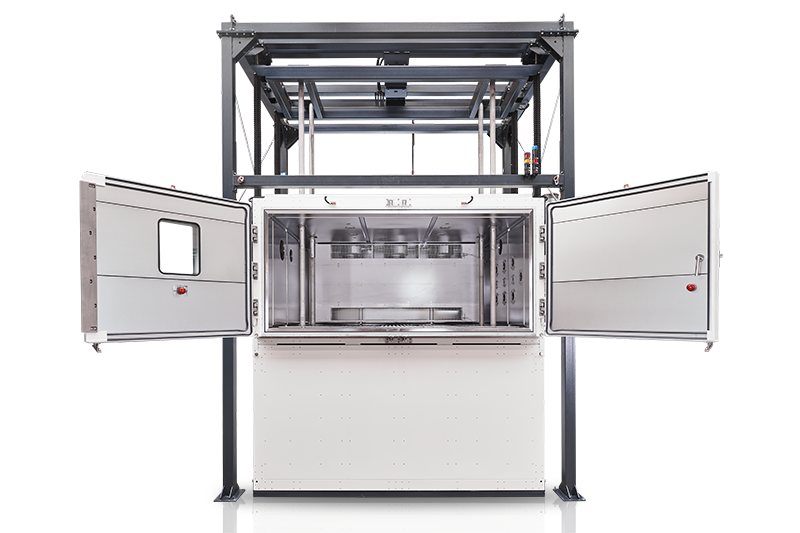

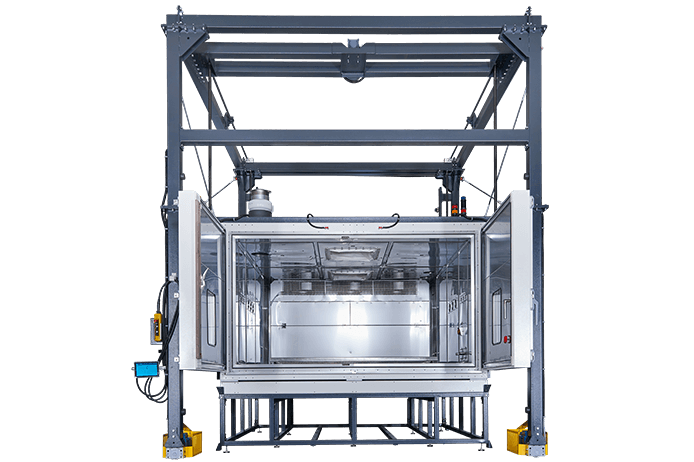

The ClimeEvent and TempEvent series are designed to meet the demanding requirements of environmental testing in battery development and validation.

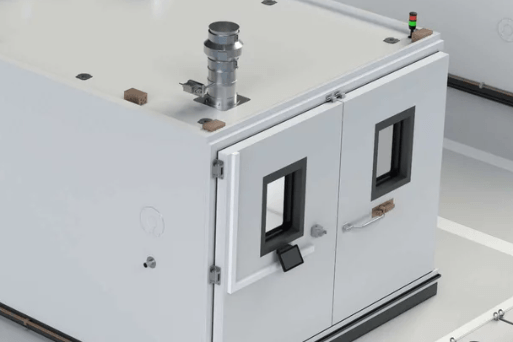

They offer precise thermal control, fast temperature changes, and full climate regulation where needed. Features like automatic water refill, a real-time status bar (green = running, orange = warning, red = fault), and remote access via optional S!MPATI software ensure uninterrupted test operation even over weekends.

Key benefits:

- Wide temperature range from –50 °C to +180 °C

- Consistent, reproducible testing even at fast ramp rates (up to 25 K/min)

- Reliable long-duration runs with automatic water refill and live system status

- Unattended operation via remote monitoring and push notifications with S!MPATI

- Certified safety up to EUCAR Hazard Level 7

- Full compliance support with absolute humidity control and documentation via S!MPATI

- Energy-efficient operation and compliant with EU refrigerant regulations thanks to CO2 refrigeration system

Perfect for:

Battery cells, modules, electronics, and system components in R&D and quality assurance.